We provide AI services for the manufacturing industry.

Implement the cutting-edge technology as a reliable workforce.

SCROLL

“We’ll accomplish The 4th Industrial Revolution”

We are a start-up from Osaka that solves manufacturing industry’s issue with unique technology of “Fast, Decent, Skilled AI”.

“Hutzper” is a neologism derived from the Hebrew word “Hutzpah”. Do not hesitate to “Dive” into AI industry with Challenges.

By making full use of our unique AI technology that meets global standards, we not only solve problems but also create added value as an “AI that can be truly useful as a tool on-site.

Visual Inspection AI for Manufacturing Indastry

"MEKIKI"

The AI solution for visual inspection available on a monthly subscription basis, which can be cancelled at any time.

Our AI substitutes for visual inspection work, contributing to the labor shortages, improving the quality, and work efficiency.

Our services, ranging from environment setup to AI operation, are provided consistently by optical specialists and AI specialists, allowing you to introduce our solutions with ease and confidence. We offer high-accuracy AI, which is usually expensive.

Data analysis with optimal forecasting algorithms

"Hutzper Analytics"

Our service lead to significant improvements in operational efficiency and optimization of conditions. Creating new insights from customer-owned data, such as Inventory optimization, Demand forecasting…etc, by utilizing AI.

Our approach involves analyzing designs and implementing specific actions to generate benefits. With insights gathered from visiting over 1,000 companies since our establishment, coupled with our proprietary algorithms, we provide tailored analyses that address challenges such as behavior detection, demand forecasting, and safety measures, tailored to meet your specific needs.

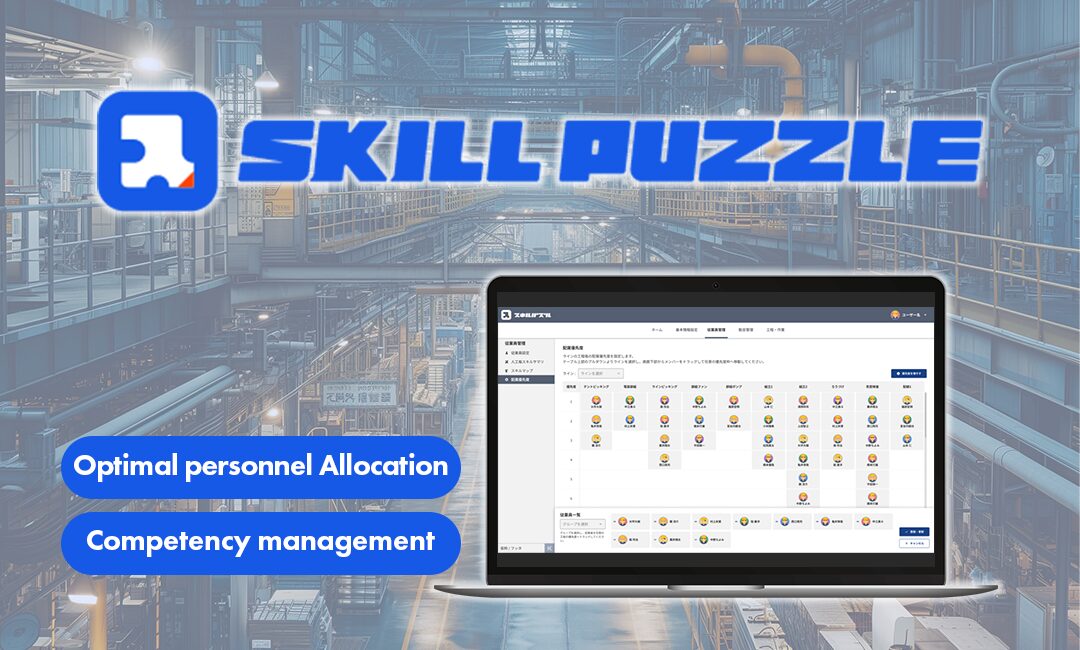

Optimaized workforce allocation AI solution

"SKILL PUZZLE"

\New release scheduled for spring 2024/

Optimizing the personnel placement within processes according to each individual’s abilities and skill management through AI.

By inputting production data, employee skills, and work conditions, our system not only proposes staffing arrangements considering productivity and skill enhancement but also swiftly adapts to unexpected changes in scheduling.

Equipped with skill management features, our solution supports the maintenance of competency matrices, contributing to workforce optimization.

Contact us

For inquiries or consultations regarding our company and projects,

we accept them through the inquiry form here. Please feel free to contact us.